We all know that equipment failure is something to be avoided, but it’s always important to understand the full threat it poses. For example, what do you do if you only have one forklift? What happens if its hydraulic hose fails when you have heavy product on the top shelf that needed moving yesterday? Without working hydraulic hoses, there’s no way you can get that forklift moving, and without any redundancy measures in place, it could take an entire day to have it fixed.

In this article, we will:

- Explain the safety precautions for handling a failed hydraulic hose

- Point out signs of wear and tear on a hydraulic hose

- Reveal the conditions that can hasten a hydraulic hose’s failure

- Highlight PIRTEK’s many services designed to keep your operation running

Safety Precautions and Damage

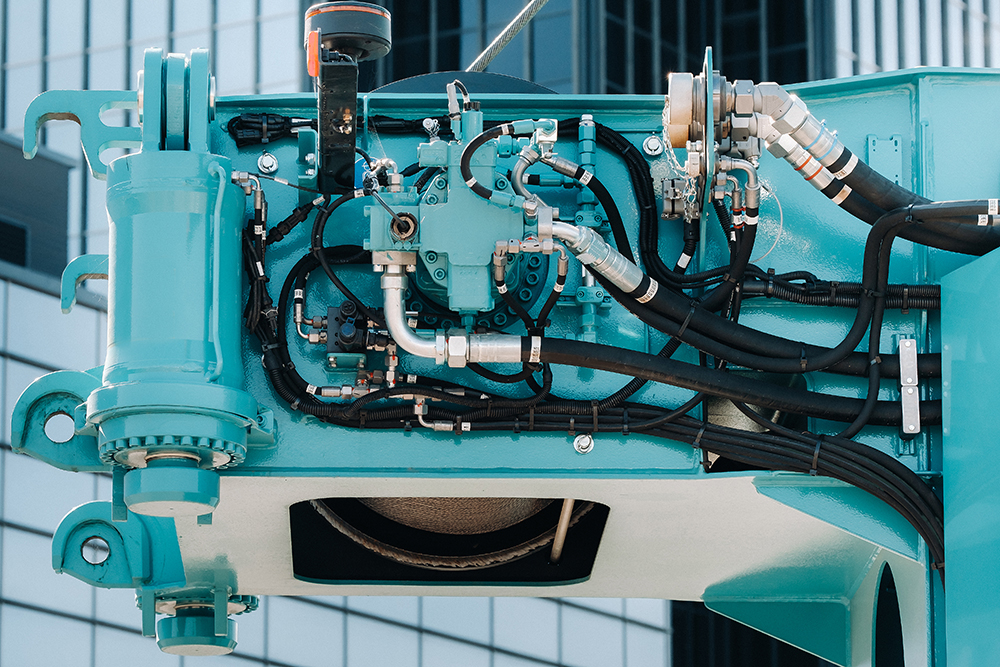

A hydraulic hose can appear so commonplace that it may not strike an operator as a potential safety hazard. But when a hose fails, it risks spurting pressurized oil that can seriously injure your employees, damage the machinery, and bring your operations to a sudden halt. Preventing a hose from failing is best done by recognizing the signs of impending failure and acting on them.

Safety First

We’re about to go over a list of signs that a hose is failing, but we need to be very clear about safety. Never use your hands to try and find a leak in a pressurized hose when it’s active. This is a straightforward way to injure yourself, as high enough pressures can pierce the skin.

Leave it to the experts and call PIRTEK for help 24/7/365. We’ll send a trained expert who can identify the leak and build a replacement hose on-site with a 1-Hour ETA.

Signs of Damage

- Exposed steel reinforcement layers

- Dry rot

- Twists, kinks, and bends,

- Leaking, cracked, or corroded fittings

- Worn patches

These are all structural weaknesses in a hydraulic hose. Twists, worn patches, and bends are weak points that the high internal pressure levels will continue to press against until the hose eventually fails. More severe issues like cracked fittings or dry rot mean the hose is on the edge of failure and must be replaced as soon as possible.

Conditions That Hasten Hose Failure

Some of the common reasons for an early hose failure are due to:

- High Temperatures – All hydraulic hoses have a limit for high and low temperatures. For example, hoses near hot equipment might run past that limit and degrade faster.

- Vibrations – Pressurized hoses are already under considerable stress, but added vibrations can cause metals to fatigue, creating weak points in the hose.

- Incorrect Hydraulic Fluid – Some hydraulic fluids may cause damage to hoses that weren’t designed to transfer them. You must ensure the chemical compatibility of the fluid is friendly with the type of hose you’re using.

- Incorrect Hose Fittings – Mating two incompatible fittings will cause the hose to leak.

- Natural Aging – Like us, hydraulic hoses do age and eventually fail. You can do nothing to stop this, but adequately taking care of a hose will keep it working for you longer.

Preventing Future Failures by Inspecting Your Hydraulic Hoses

An easy way to do this is to instruct your forklift operators to commit to a safety checklist before each shift. They should ensure that all necessary components, including the hydraulic hose, are working as they should. The operator should ensure that there are no:

- Kinks, bends, or otherwise worn patches

- Patches of dry rot on the hose, cracks in the fitting, or obvious leaks upon startup

- Missing or damaged clamps meant to hold the hoses in place

- Hoses trailing off or riding loosely over sheaves and pullies

Practicing this checklist will not only keep your operator safe, but it’s also a great way of pinpointing when the hose begins to wear out. If you catch a problem early, you can stop it from worsening. For example, suppose the operators notice the hose degrades after less than a year. In that case, they can determine whether the hose is getting too hot, vibrating too much, or bent at an extreme angle and fix the problem before the hydraulic hose sustains more damage.

How Can PIRTEK Help?

PIRTEK is more than just a hydraulic hose supplier; we provide various services to our customers to help keep them running at peak efficiency. Take the example we mentioned at the beginning of this article. What happens if your hydraulic system fails and you only have one forklift? You can take advantage of our On-Site Mobile Hose Service and have the hydraulic hose replaced in a couple of hours rather than a couple of days.

Alternatively, why let your equipment fail in the first place? By taking advantage of PIRTEK’s Preventative Maintenance Program, you can help prevent a hose failure from happening in the first place. Our survey will determine the operating health of your hydraulic hoses and identify those that require replacement and those in good condition. In conjunction with our Hose Tagging System that identifies when each hose we make was put into service and their other specifications, you can drastically reduce the likelihood of a premature failure.

Check our website for more information on the products and services we provide. You can find your closest PIRTEK location by entering your business address into our search tool. For all your forklift hydraulic hose maintenance and replacement needs, call PIRTEK!